Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

YeZhang,GaoYukui

(School of Aerospace Engineering and Applied Mechanics,Tongji University,Shanghai200092,China)

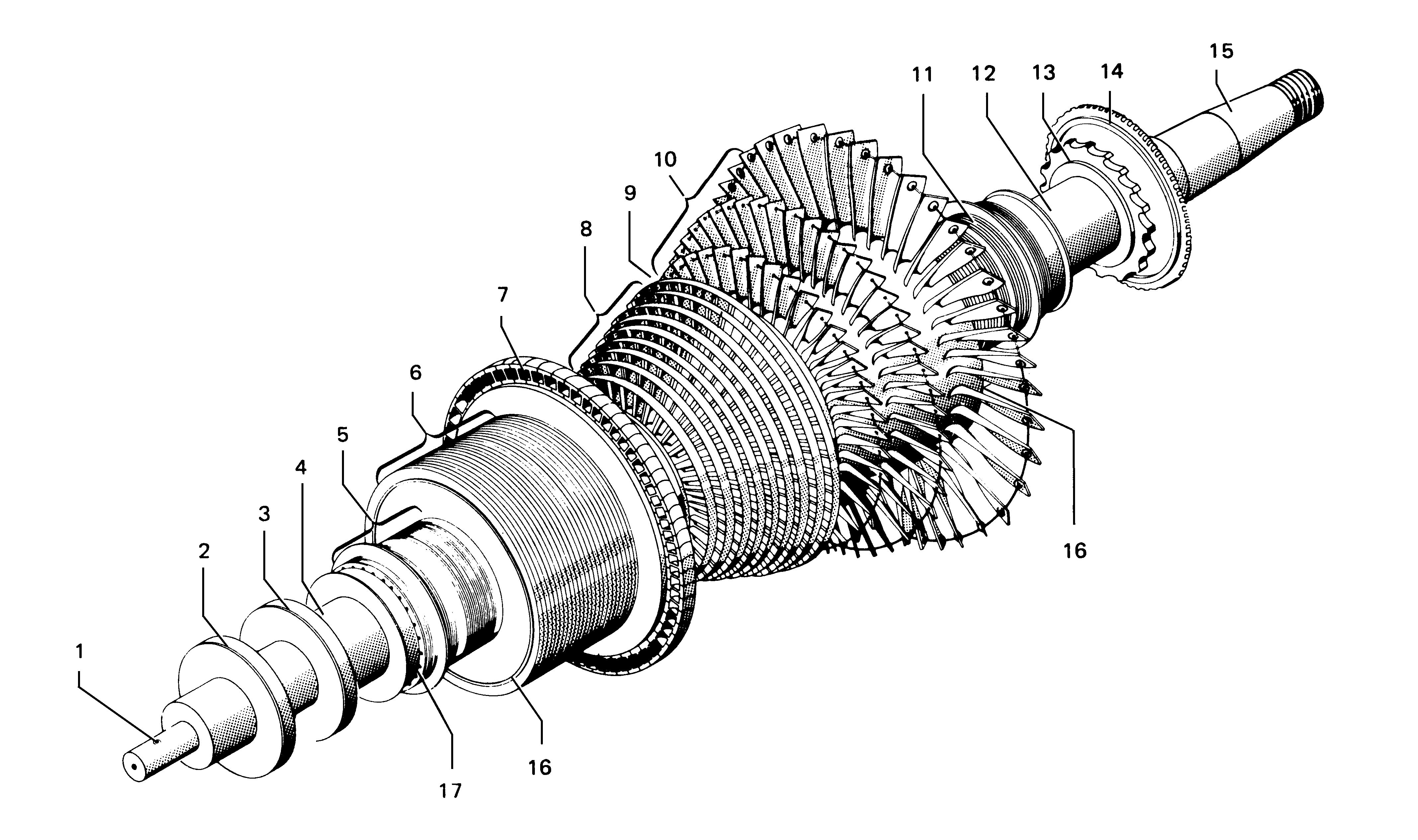

Abstract:The residual stress is produced during the forging of alloy GH4169 turbine disc to affect the integrity and mechanical properties of the turbine disc.So the forging process of alloy GH4169 turbine disc was numerically simulated by DEFORM-2D,and the distribution of residual stresson the turbined is cwasobtained.At the same time,the surface residual stress of the turbined is cwastested by XRD (X-raydiffraction),and the results of DEFORM-2D numerical simulation were compared. At last,the results were close,and the results of DEFORM-2D numerical simulation were ideal.Then,the hot die forging technique of turbine disc was optimized based on orthogonal experiment,and the influences of different process parameters on residual stress during turbine disc hot die forging were analyzed.The results show that turbine disc with lesser residual stress can be obtained with billet temperature of 1100°C,die temperature of 1050 °C,deformation rate of 2mm.s-1 and friction coefficient of 0.2. However, the residuals tress on the turbine disc is mainly concentrated in the radial direction,and the high residual stress appears at the fillet residual hub,wheel coreand the flange surface proneto crack easily.Further more,the billet temperature has the most important influence on the residual stress of the turbine disc,and the second influence factor is the die temperature.But the influences of the deform ationrate and the friction coefficient on the residual stress of the turbine disc are small.

Keywords: alloyGH4169; hot die forging; DEFORM-2D; turbine disc;residual stress;X-ray diffraction;orthogonal experiment

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com