Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

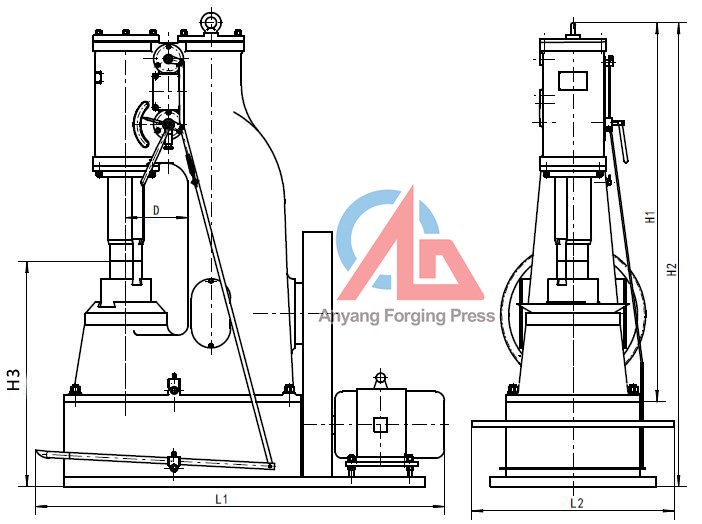

Anyang FP Power Hammers for blacksmiths (from 15kg to 110kg) are self-contained pneumatic power hammers. The design is based on the time-proven designs of the old European hammers many of which are still in use today. With a self-contained power hammer, you require no external air supply or high-pressure hoses.

The frames are cast iron, like the old Nazel, Beche, and Massey hammers. Cast iron is more expensive to manufacture compared to fabricated hammers but they are heavier, do not flex over time, and have a lifetime warranty on the frame.

Anyang FP Blacksmith power hammers hold their value well and come with a full warranty. Due to their long lifespan and high build quality, used Anyang power hammers are difficult to find. Sales of used Anyang models are usually close to those of new retail models.

The Anyang FP power hammer is designed to give you many decades of maintenance-free forging. But there are several maintenance items that are important:

1. There are two grease zerks for the crankcase and connecting rod. These grease points should be greased at least once a month. Pump enough grease where you see grease coming out from the bearings or where the shaft exits the crankcase.

2. Using the proper type of oil is important to hammer life and performance. I recommend using 10 to 30 weight (depending on the temperature of your shop). If your oil is not flowing adequately then use a lighter oil. Even in Texas, I use 10 wt. oil most months. It is also important to use non-detergent oil. Oil is consumable (it is not recycled) and operating temperatures are low (compared to car engines) so it is not important to purchase expensive oil. I buy the lowest-cost oil that I can find from the local agriculture supply store. I also purchase it in 2.5-gallon bottles.

3. The most critical component of power hammer performance and life is the amount of oil you use. Oil is not only a lubricant, it is a "sealer". On all of the new hammers, we have eliminated the front oiler to the ram. The rear compressor piston is always circulating when the hammer is running and it always needs an oil supply. The front ram will be fed oil from the rear compressor through the air valves. I recommend that when you first start the hammer, turn the oil valve all the way up and get the oil flowing. When you start forging, you can then adjust the oil down. I recommend trying to dial the oiler to one drip every 3 to 6 seconds. With proper oiling, the ram will be 'moist" with a film of oil. I also say "if you make a mistake, use too much oil... it never hurt the hammer." Too little oil long-term will shorten the life of the hammer... just like a car engine.

4. Once a year, check the plastic oil lines for stiffness, discoloration, or cracking. Replace them if necessary. The plastic lines can be purchased for a dollar or two at a local building supply store.

5. After a few hours of forging, tap on the die keys to make sure they are tight.

6. Once every two months, check bolts for tightness. After the first 6 months of usage, check the connecting rod nuts for tightness.

7. Depending on your usage, every two or three months drain the oil at the bottom of the power hammer using the petcock on the side of the power hammer.

The new Anyang L type Power Hammer besides all the above features also has a heavier frame and ram design where the key and die do not retract into the cylinder making it easy to change dies and use tooling. You can forge heavy stock and immediately switch to thin light stock with no adjustments. With a self-contained power hammer, you have tremendous forging power (a combination of ram weight, downward air force, and velocity) plus precise control.

Anyang L type power hammer is patented product, All Rights Reserved.

PS: L type power hammer the tup die will not retract in to the cylinder, and the throat depth is deeper.

Alec Steele Test Run Anyang 75kg Power Hammer in His New Shop, Montana, USA

Anyang Gray power hammers for North America dealer - www.anyangusa.net

Anyang Power hammers for Australia dealer

Anyang Power hammers for Germany dealer

Anyang Power hammers for UK dealer

Anyang Power hammers for France dealer

Anyang power hammer working in USA

| Market Area | Contact Person | Website | Location | |

| USA, Canada, Mexico | James Johnson | USAforging@gmail.com | 2955 CR 1370 Alvord, TX, USA 76225 | |

| Australia, New Zeeland | Bruce Beamish | bruce@anyangaustralia.com.au | https://www.anyangaustralia.com.au | Unit 4&5 51-53 Della Torre Road, Moe, 3825 Victoria |

|

UK

|

John Nicholson | sales@masseyforging.com | http://www.anyang.co.uk | Hyde, Cheshire, UK |

|

Germany, Belgium

|

Johanes Angele | info@angele.de | http://www.angele-shop.com/ |

If you want a larger 150KG-2000KG Power Forging Hammer, please click here:

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com