In the field of forging equipment, both fully hydraulic die forging CNC hammer and electric screw press are popular choices. They each have unique advantages and can meet different production needs. To help you make a better choice, we will compare them from the following aspects:

Working principle

The fully hydraulic die forging CNC hammer uses a hydraulic system to drive the hammer head to perform up and down linear strikes;

The electric screw press uses a motor to drive the flywheel to rotate, and converts the rotary motion into the linear motion of the slider through the screw pair.

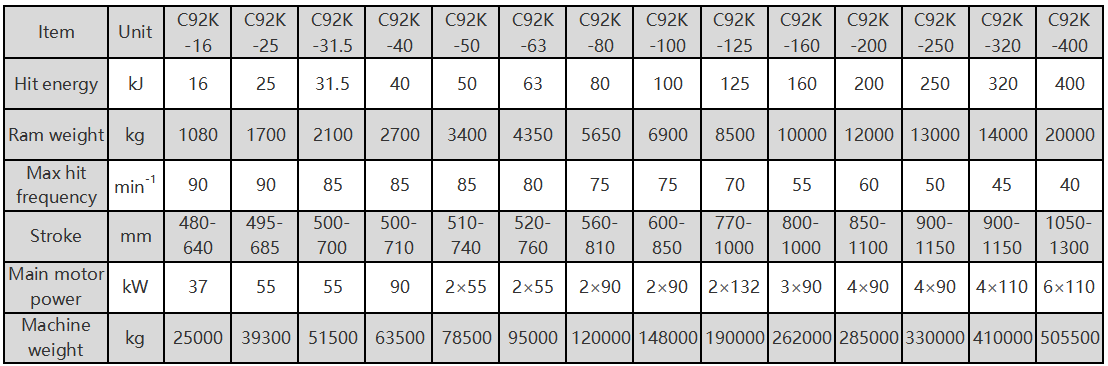

Fully hydraulic die forging CNC hammer:

High striking force and high forming efficiency: The hydraulic system can provide strong striking force, which is particularly suitable for the processing of large and thick-walled forgings, and can significantly improve production efficiency.

Low mold cost: Due to the reciprocating striking method, the precision requirements for the mold are relatively low, and the mold manufacturing cost is also low.

Low equipment investment cost: Compared with electric screw presses of the same tonnage, the equipment cost of fully hydraulic die forging CNC hammers is lower.

Flexible operation: The striking speed and striking force can be flexibly adjusted according to different process requirements.

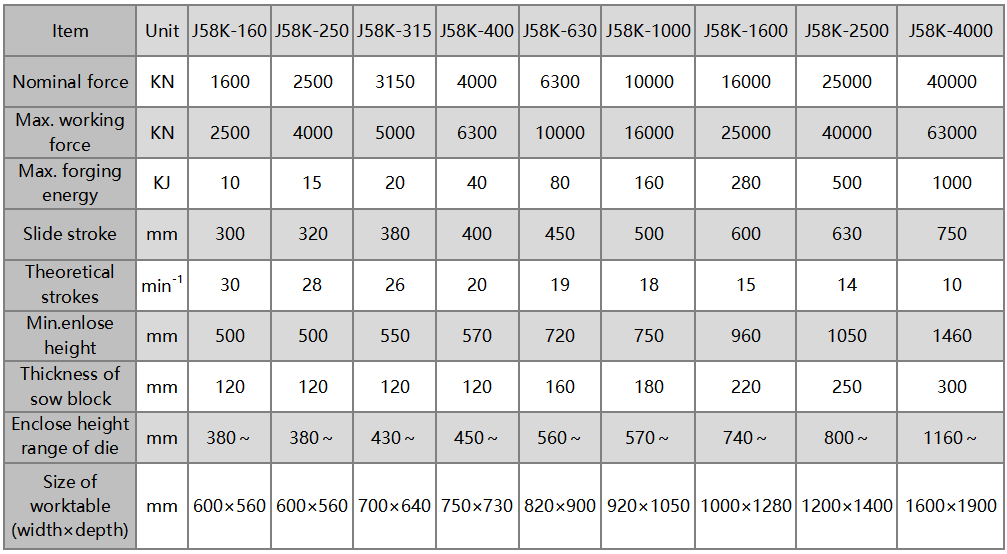

Electric screw press:

High striking accuracy and good production stability: The energy and stroke of each strike can be precisely controlled to ensure the dimensional accuracy and consistency of the product.

Energy saving and environmental protection: The motor consumes electricity only when it is working, and the energy utilization rate is high and the operating cost is low.

High degree of automation: It can realize automated production with robots, feeding devices, etc. to improve production efficiency and safety.

Low noise and low vibration: The equipment runs smoothly, with less noise and vibration, improving the working environment.

Full hydraulic die forging CNC hammer and electric screw press each have their own advantages. The choice of which equipment needs to be comprehensively considered according to specific production needs, budget and product characteristics. If you need to process large, thick-walled forgings and are sensitive to cost, then the fully hydraulic die forging CNC hammer is a better choice. If you need to process precise, complex forgings and have high requirements for production efficiency and product quality, then the electric screw press is more suitable for you.