Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Introduction of electric screw press

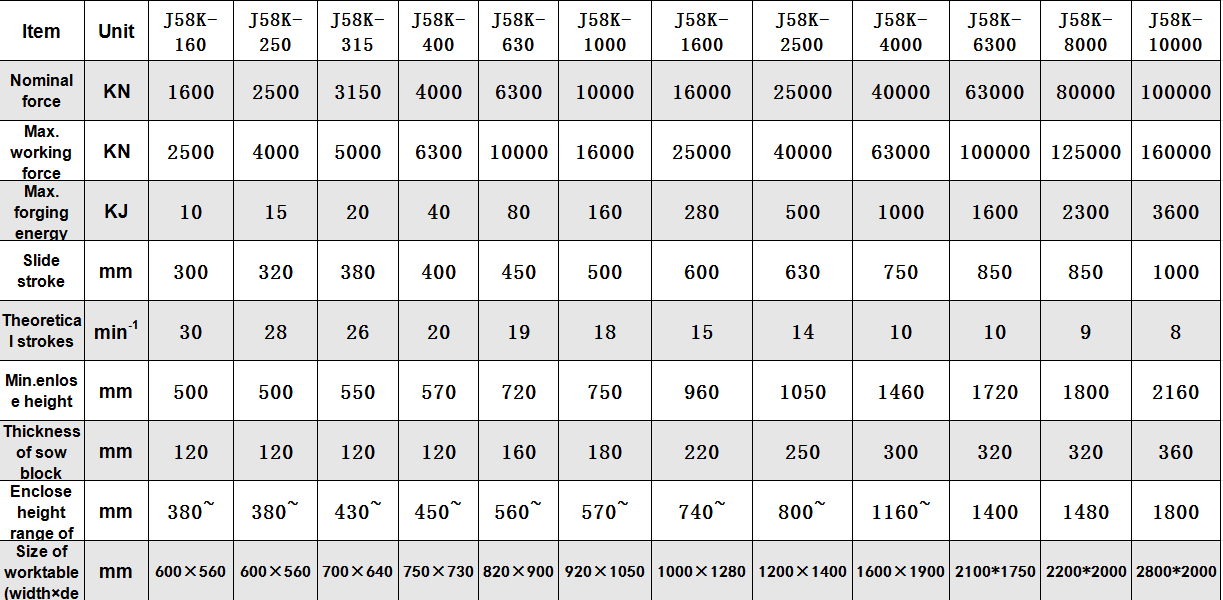

J58K Series Electric Screw Press/suitable for all kinds of precision forging, sizing, precision pressing, calibration and leveling, etc processes. The hitting energy can be accurately set, the stroke is short, and the energy is stable. The hitting energy can be adjusted according to the metal forming needs to reduce the mechanical stress and thermal stress of forging dies, prolong the lifespan of the forging dies. Because of its low slider speed, it has unique advantages in forging non-ferrous metals such as aluminum alloy and copper. The J58K Series Electric Screw Press produced by our company adopts advanced frequency conversion control technology, it has a simple and reliable structure, can provide greater working energy, also it has the following features and advantages to make it widely used in forging production.

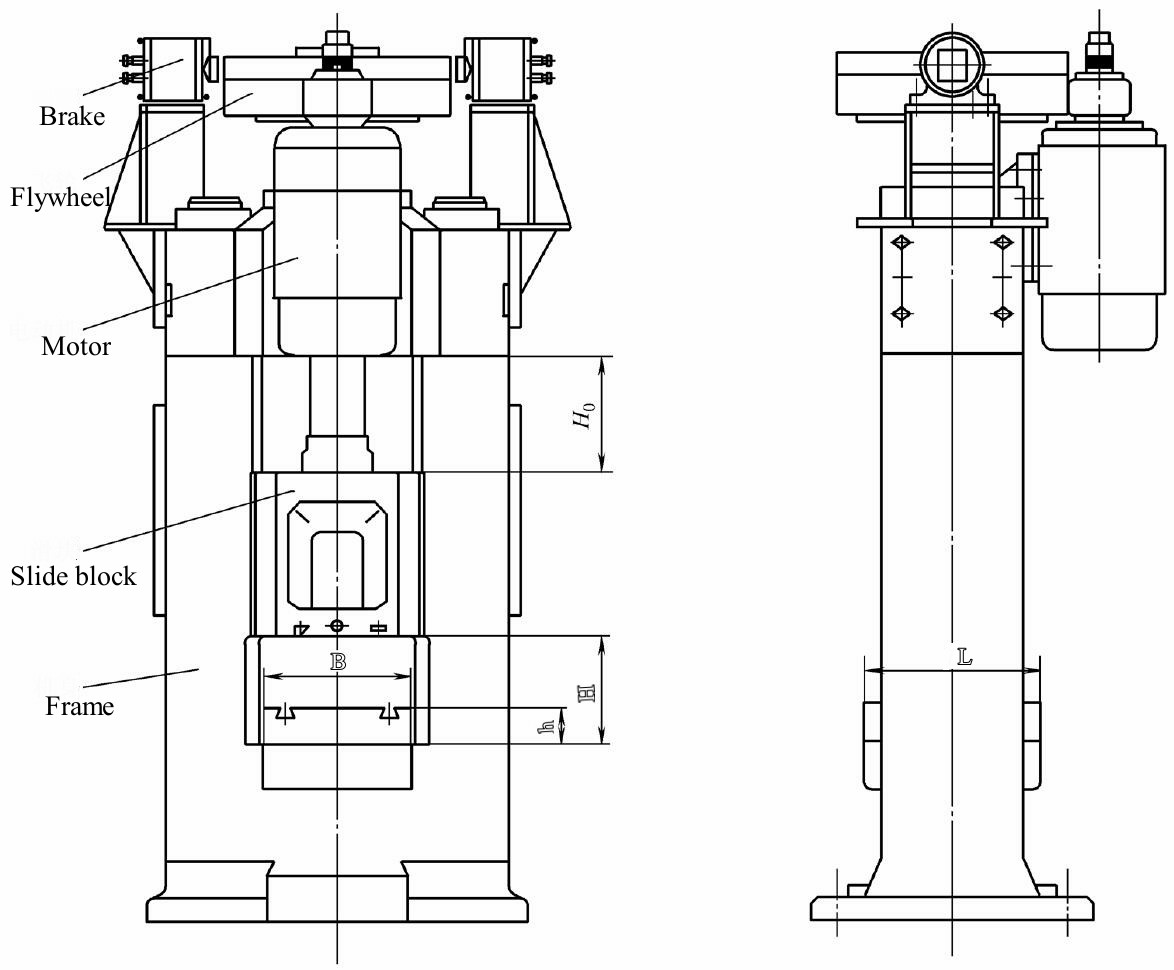

Electric screw press structure diagram

The slide moves up & down driven by the motor through pinion, gearwheel, and screw, gearwheel has enough inertia to act as a flywheel. After input start signal, motor from stationary state drives slides to accelerate downwards through pinion and gearwheel, motor stop accelerating after reaching required speed by pre-set blow energy, Kinetic energy stored by gearwheel works, e.g. forming work. At the same time, the motor immediately drives the gearwheel to reversal rotation, when reaches a certain point, the motor will start to brake, drives slide back to a pre-set position. Since brake is by the motor when the slide is in return stroke, mechanical brake only works when the slide is close to the up dead point, brake material is not easy to wear, no need for frequent change.

Our electric screw press adopts gear drive mode, features of this drive mode are: adopts special motor, high RPM, less torque, different tonnage press with different power special motor, easy to replace when motor breaks down, easy & simple maintenance, motor performance is not affected when screw guide bushing is worn out., the efficiency of electric screw press improved a lot with continuous improvements & innovations in many years, this gradually established our leading position in electric screw press market.

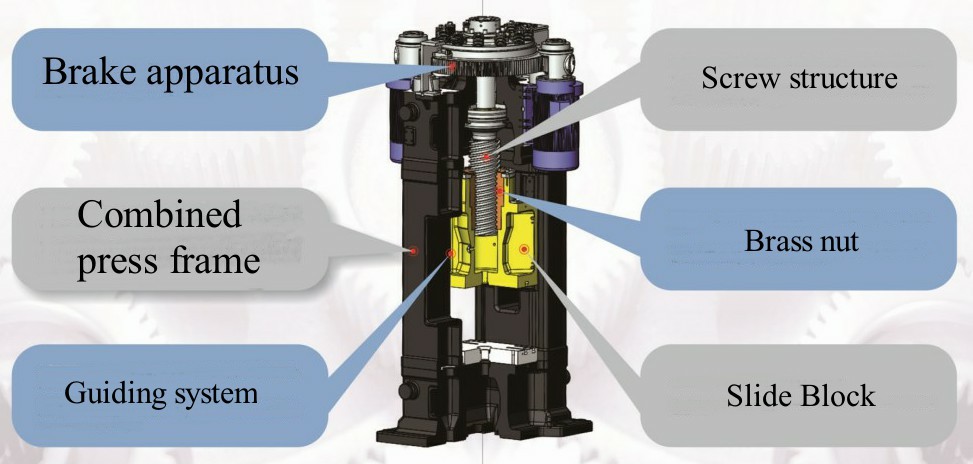

Screw structure:

The screw is CrMoV high alloy forging, thread type has good fatigue resistance, no self-lock, stable installation, short screw, increased press rigidity.

Nut:

Made of bronze material, installed inside the slide, has good abrasive resistance and emergency sliding performance.

Slide Block:

The slide block is using high-class steel casting with full aging treatment to relieve stress.

Guiding system:

The guiding system has a 45-degree arrangement with the slide block surface, to keep constant clearance and not be affected by the thermal expansion. The guiding set is using bronze and steel. The guide rail with nitrogen treatment, the guide plate can be adjusted from each direction to ensure the smallest guide rail clearance. The slide block guiding length and rigidity etc. can ensure to produce the high-quality products with long die life.

Brake apparatus:

The brake directly affected by gear makes it braking at any position, the brake is closed through spring force, and the opening is pneumatically controlled.

Driving unit:

The precision screw drive is driven by a squirrel-cage three-phase positive and reverse asynchronous motor, this kind of driving unit with low maintenance and high-reliability features.

Lubricating oil circulation:

There is a monitoring lubricating oil circulating system to lubricate the spiral thrust bearing constantly. The guide rail lubricating features will sustain in numbers of circulation.

Combined type press frame:

There is a number of advantages of the combined type frame, to eliminate the notch stress centralization between the working table and columns, between the crossbeam and columns. The large size of the forging press can be dismantled and transported in several pieces. The frame adopts a pre-stressed connection with high rigidity, under the same tensile stress, the extensibility is only 20% of the unibody designed frame.

The electric screw press is the key equipment, Anyang forging press company can supply the forging production line for the customers, including cutting equipment, heating equipment, preform forging equipment, forging robots, Trimming equipment, and integrated system, etc.

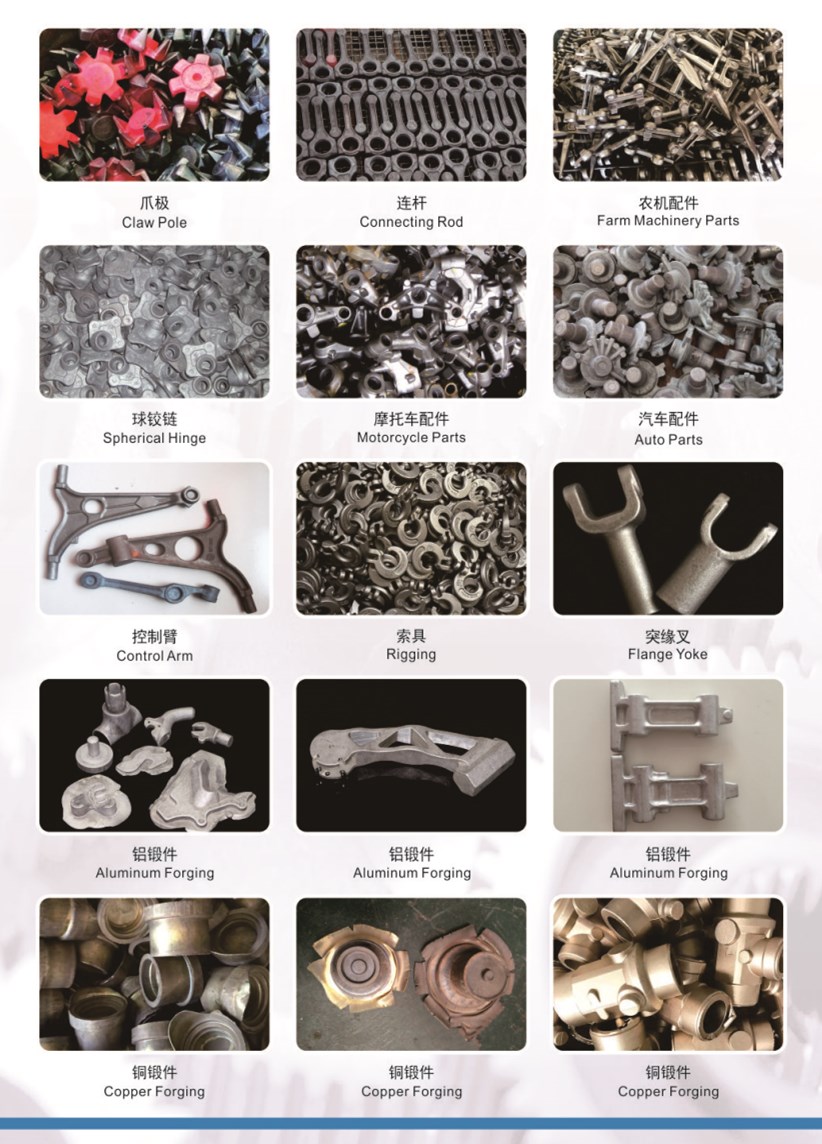

An Electric Screw Press can forge Claw Pole, connecting rod, form machinery, spherical hinge, Auto parts forging, control arm, riggings, etc steel forgings. also can forge Brass, Aluminum, etc Non-ferrous metals.

Anyang electric press forging gear

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com