Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Hydraulic riveting machine is adopted full hydraulic drive and control, when output pressure, it can achieve cold riveting directly, improve the quality of hydraulic riveting machine. Comparing with traditional pneumatic riveting, hydraulic riveting machine has following advantages: the working condition is good, no noise, operation is agility, labor intensity is low, rivet speed is high, and the production efficiency is high.

It can be used for punching, press-fitting, print and forming when assembling corresponding device

1. The specification of a rivet is usually confirmed according to GB863.l - 86GB867- 86、GB864- 86 、GB868- 86 、GB865- 86 、GB869- 86 and other standards.

2. The material of rivets is generally Q235 、F l 、F2 or other plasticity material.

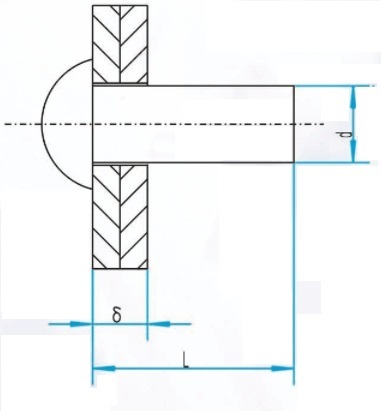

3. The length of the rivet is calculated according to the following experience formula.

L-rivet l e ng t h (mm)

d-rivet diameter(mm)

δ - T he w id t h of rive t parts

|

Rivet diameter(mm) |

8 | 10 | 12 | 14 | 16 |

|

Riveting force(ton) |

16 | 20 | 28 | 40 | 50 |

Riveting force F=l0d² π/4 (ton) d is rivet diameter (cm)

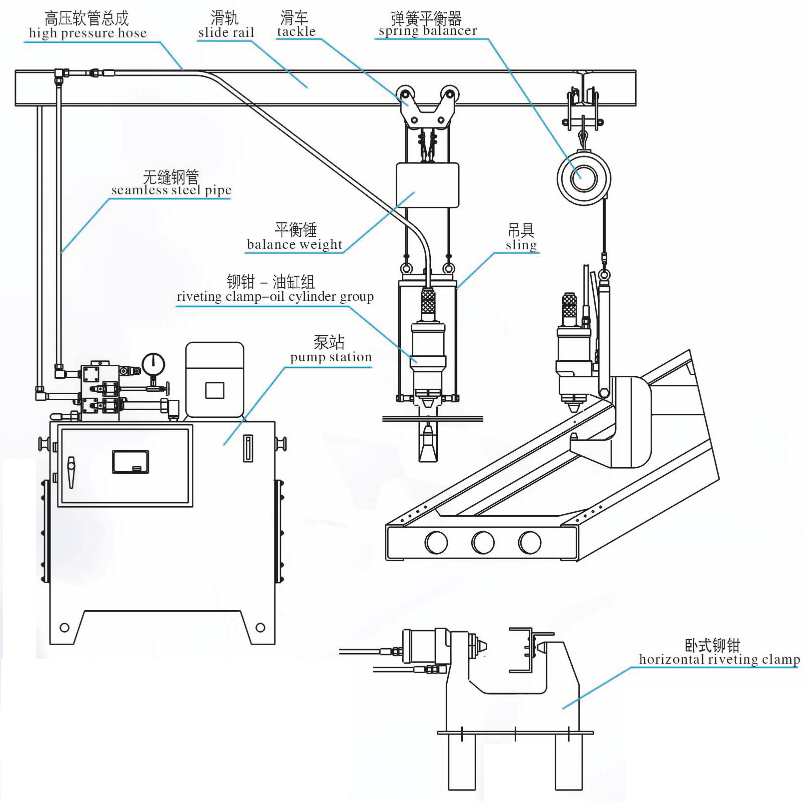

The hydraulic Riveting Machine consists of the pumping station, rivet clamp, sling, high-pressure hose, balancer, tackle, slide rail, working oil cylinder, accessories, and so on. The layout and installation are set up according to the requirements of the product line. The detailed install structure is as follows.

1. The slide rail (16# double iron) and seamless steel pipe are prepared by the users according to their requirements.

2. The balancer of hanging rivet clamp has two kinds: balance weight and spring balancer, the user can choose one of them.

3. The working form of the riveting clamp has two kinds: hanging and horizontal type, and the horizontal type is mainly used in riveting the hanging parts at the two sides of the frame.

4. The hydraulic pumping station is divided into single riveting and double riveting, the single riveting can drive a riveting clamp and double riveting can drive two riveting clamp

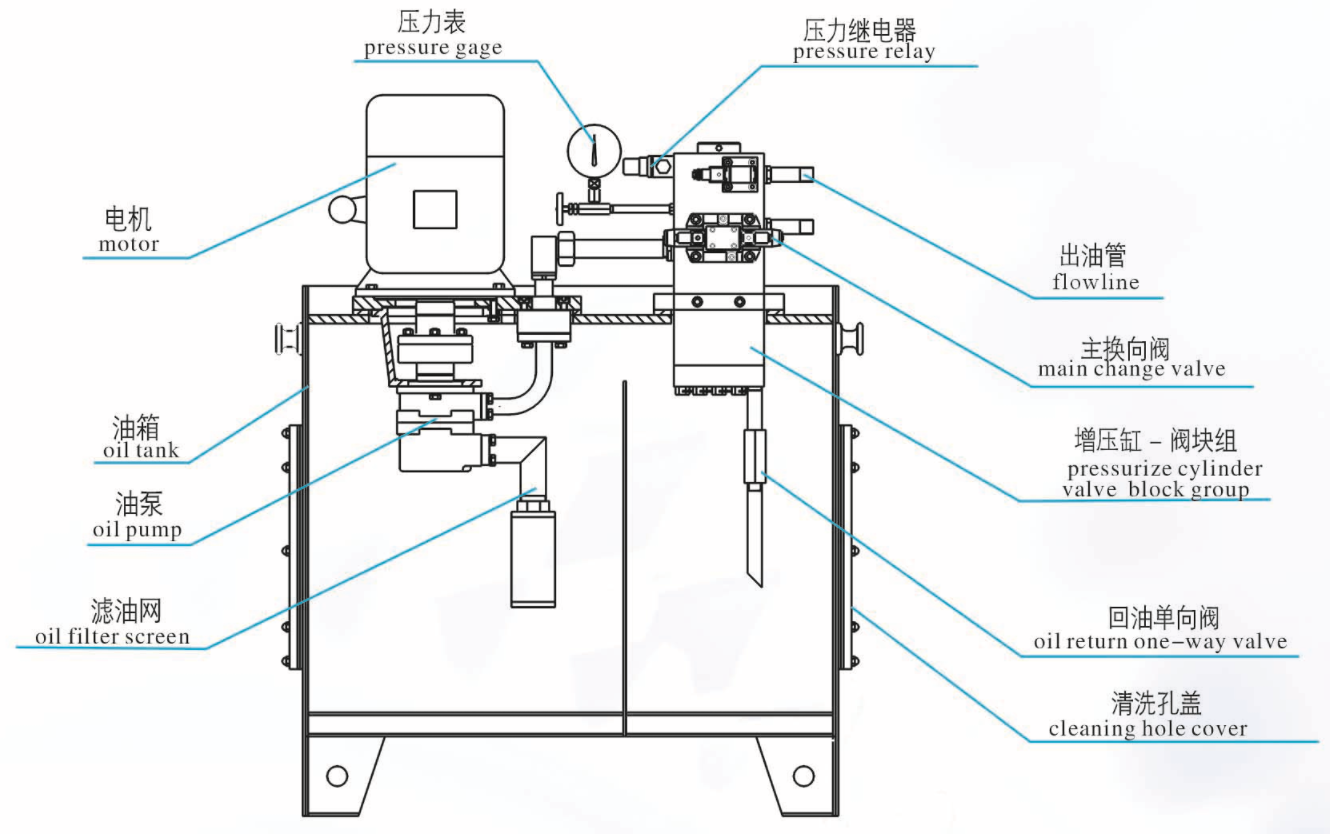

The central control part of a high-speed hydraulic riveting machine is the hydraulic pump station, and its performance influences normal production. We have produced the machines for more than 20 years, so we have accumulated more experience. Because of the development of the automobile industry, machines have developed dramatically During technical innovation in 20 years, the performance has motivated dramatically, the hydraulic system is more stable, and maintenance is more convenient.

1 、The pressurize cylinder and valve block are identical entities and the volume is too small, and the oil line is too short, this can reduce the leakage and heat, and enhance the longevity

2 、 The system used the mass flow cartridge inserted valve, this

the component has several advantages as follows: mass flow, better leak proofness, anti-pollution,wearproof, and so on

3 、 The oil pump adopted the Italia n ATOS series pump, it 1s high pressure, less leakage, and low noise

4 、 The control slide valve adopted LISHILE series valves, change

over is stable and the noise is low

5、Electrical control is controlled by PLC, it is stable and easy to modify,

6 、 The design of the hydraulic system is eligible, so the rivet speed is high, and the efficiency is high

7 、 We can install the mass flow air patenting cooler according to the customer's requirements, so it can be used in the tropical region.

8 、 The special machine work equipment ensured the precision of components, stability, and longevity of the machine.

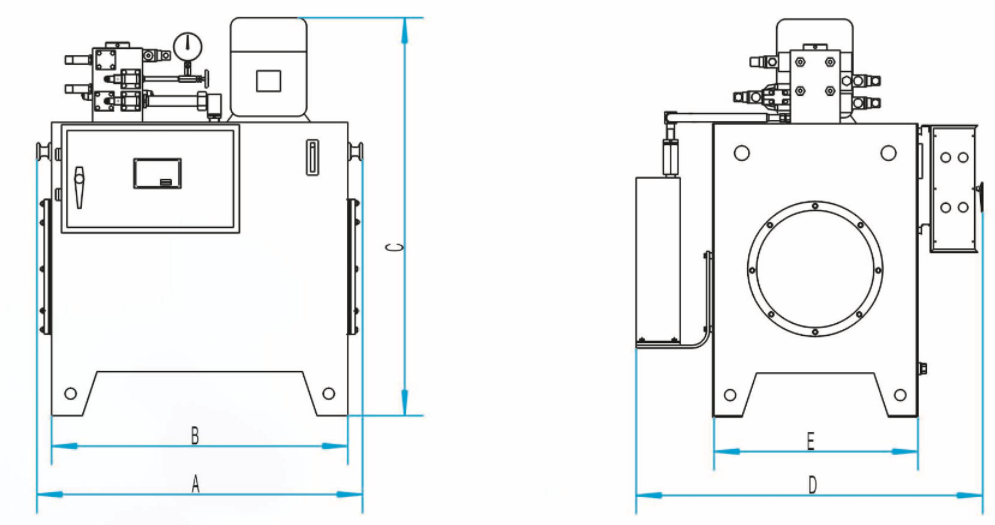

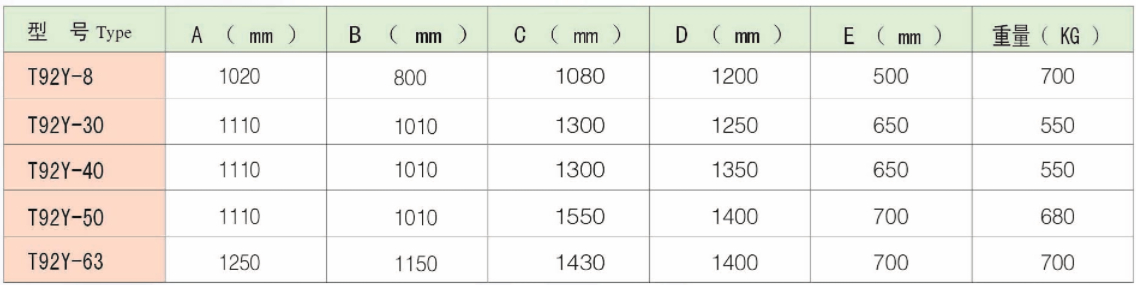

1. T92Y series pump station should be equipped with the same tonnage riveting cramp, and it also can be equipped with the adjacent tonnage riveting cramp, but the riveting rate will be increased or decreased.

2. The riveting rate is the same tonnage pump station equipped with the riveting clamp, the go and back per minute of continuous running under the normal le ad 80mm cond 山 on.

3. T92Y series pump station includes double-riveting and single

- riveting, the user can choose it according to their use condition.

4. There isn't equipped chiller when the pump station.

leave the factory, the user should be prepared according to their work condition.

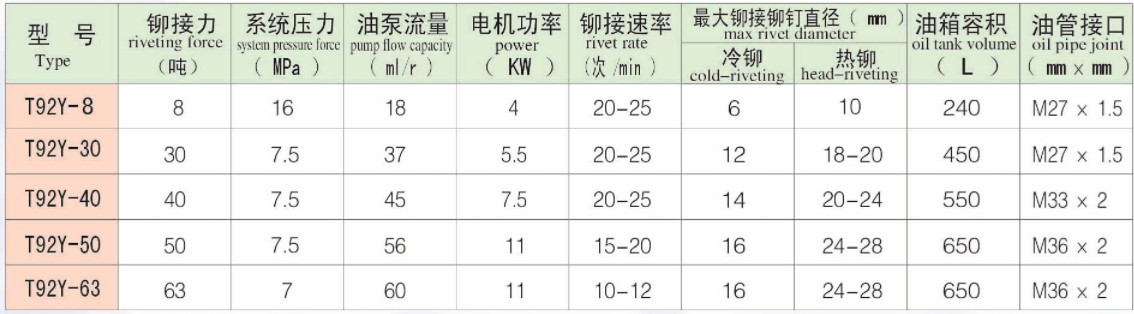

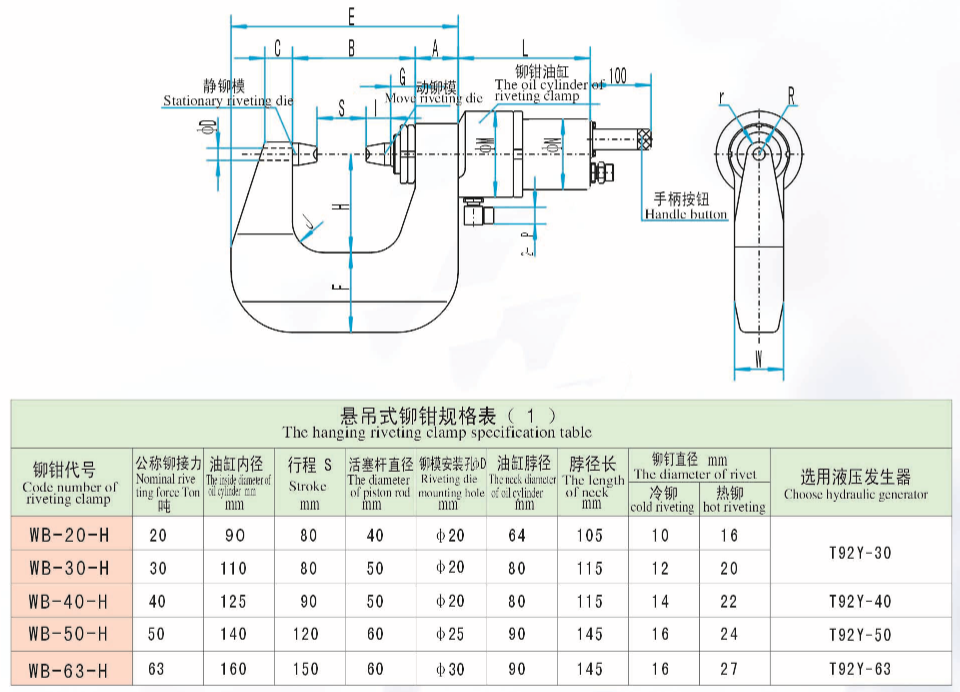

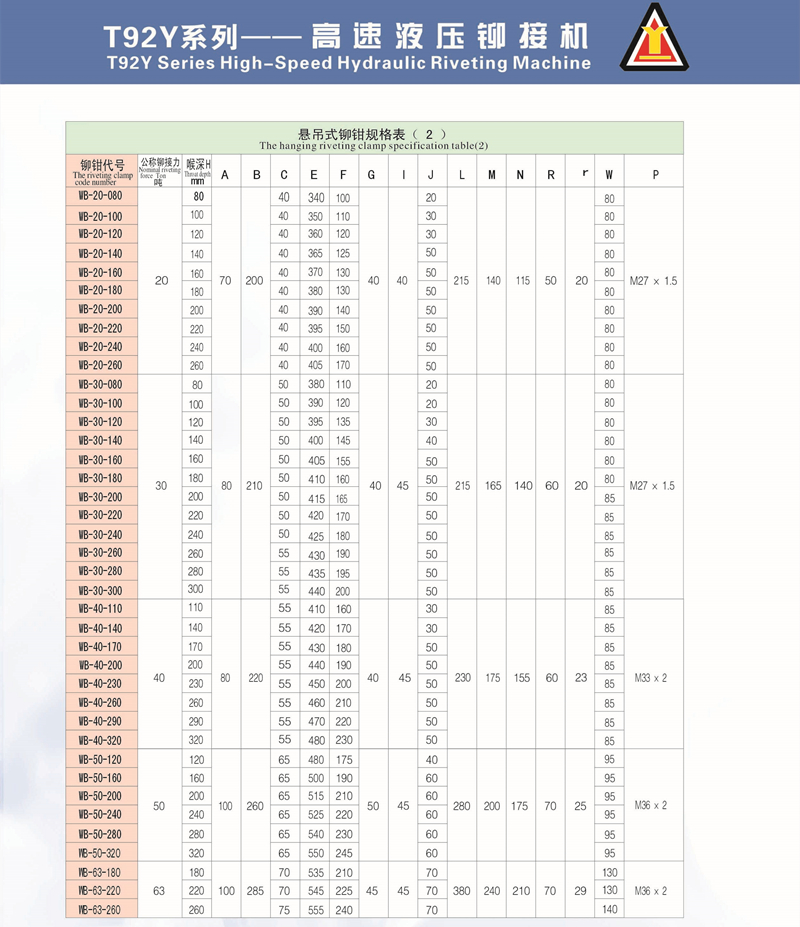

•There are two types of the riveting clamp: hanging and horizontal, and the hanging riveting clamp is used widely. The main components are the oil cylinder, the body of the riveting clamp, the move riveting die, the stationary riveting die, and the handle button.

•With the hanging riveting clamp, in order to ensure the performance of the riveting clamp, reduce the weight as soon as possible at the same time, and make the operation is handiness and agile, the body and oil cylinder of the riveting clamp adopts the high-quality special steel product.

•In order to suit the various shapes workpiece and the size of the rivet diameter, we make the riveting clamp in series so that the customer can choose. For the special request riveting clamp. you can contact our company at any time.

Explanation:

1. Model explanation

W: The throat depth of the body of the riveting clamp (as the riveting clamp specification table(2)

Number: Nominal riveting force ton.

H: Riveting clamp code

2. Choose the riveting clamp according to rivet diameter

3 .The riveting clamp specification is shown in the hanging riveting clamp specification(2)We can make the special specification according to the customer's request.

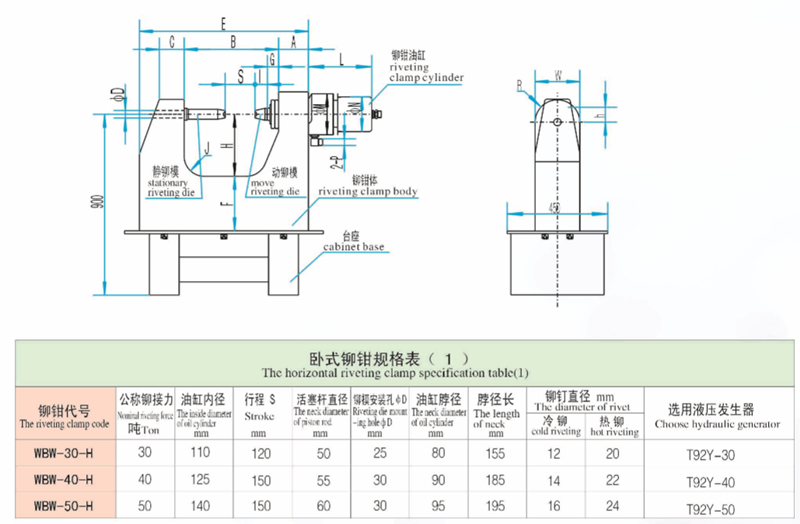

Explanation:

1. Model explanation

W: The throat depth of the riveting clamp (as the horizontal riveting clamp specification table2)

Number: Nominal riveting force ton.

H: the horizontal Riveting clamp code

2 . The riveting clamp specification is shown in the horizontal riveting clamp specification(2), We can make the special specification according to the customer's request.

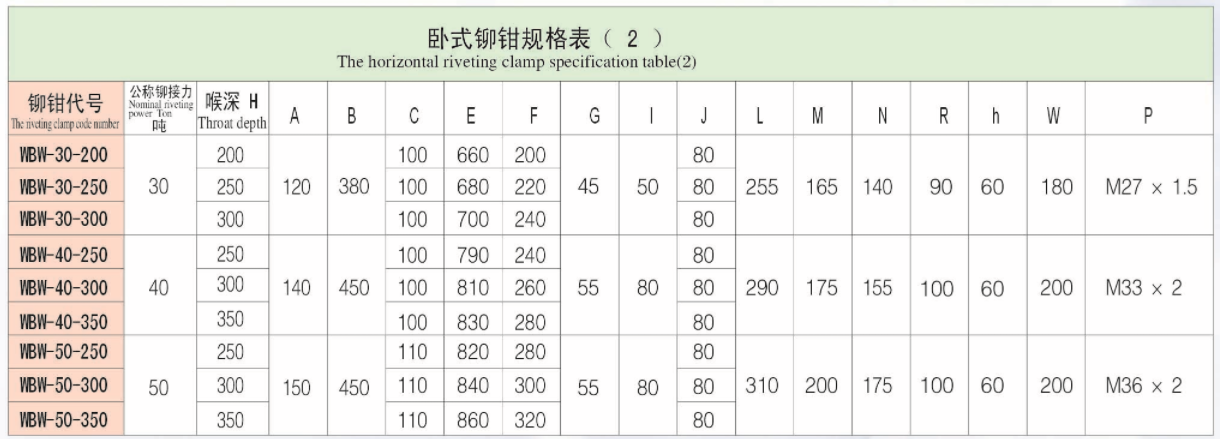

Riveting die can be divided into move riveting die and stationary riveting die, they are installed on the piston rod and riveting clamp respectively (The horizontal stationary riveting die is installed on the riveting clamp through the riveting die cover). The size of the riveting die is fit for all kinds of shapes of rivet of standard series, and we can make the special request riveting die. Generally, the A-type riveting die is used for hanging riveting clamp, B riveting die is used for the horizontal riveting clamp.

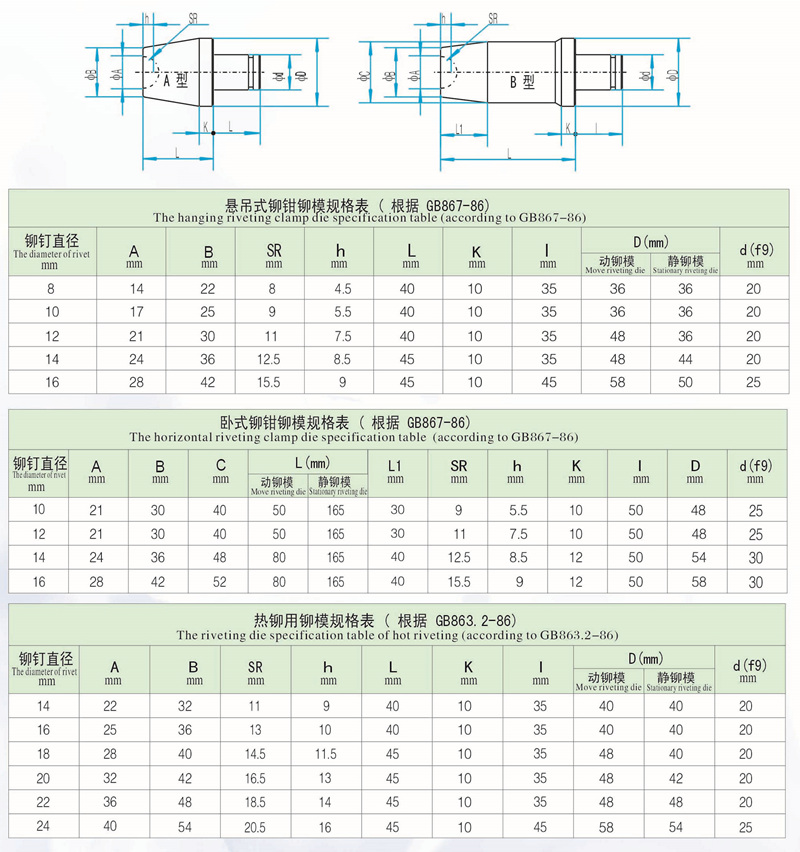

The hanging riveting clamp is installed on the hanging device to work, with the hanging device, the riveting clamp can move freely, so it can aim at the riveting part quickly. The hanging device has several styles, it can be divided into balanced weight hanging devices and spring balancer hanging devices according to the balance style. The install structure is as follows:

Balance weight or spring balancer is installed on the part between the tackle and the riveting clamp, they are used to balance the riveting clamp's weight. When we operate the riveting clamp, we can move the riveting clamp thereabout and left right easily. The balance weight is made according to the riveting clamp's weight. Spring balancer is a purchased part, we can choose the size of specification according to the riveting clamp's weight.

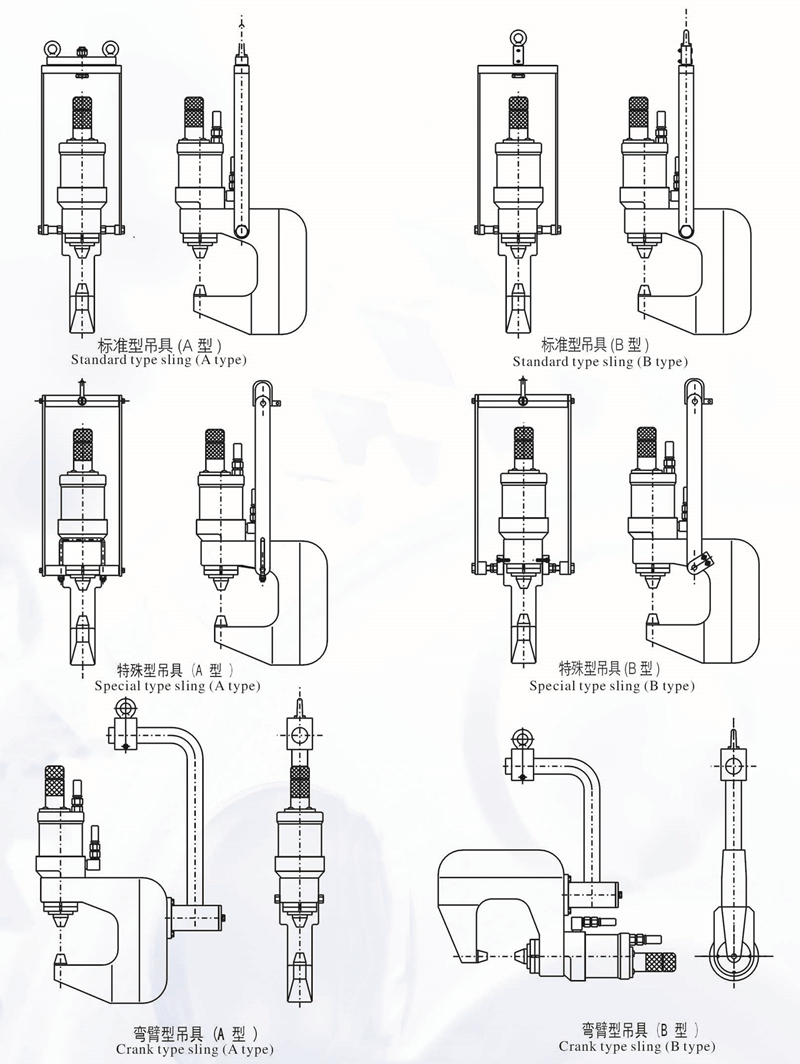

In Accordance With the different requirements of usage, the sling can be divided into several general types as the following diagram. The standard type and special type slings can be revolved 180", and they can be used to rivet the common workpieces. The crank type sling can also revolve 180", and it can be used to revolve the inclined angle workpieces. We provide the standard type sling when our products leave the factory, if the customer has special requirements, please note the specific requirements when ordering.

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com