Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

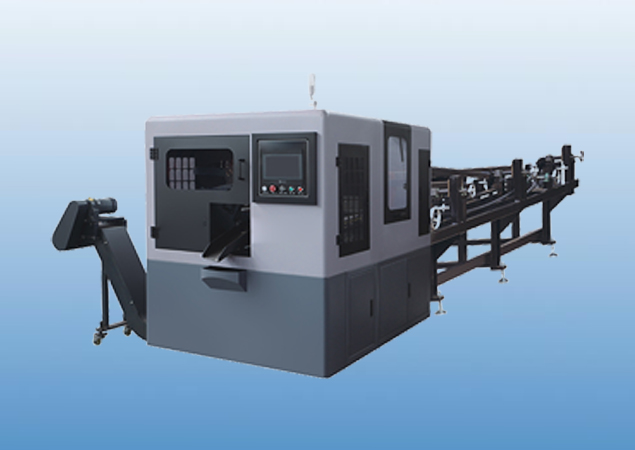

The main components of metal circular saw

The fully automatic high-speed metal circular saw machine mainly consists of the machine tool bed, power head part, feeding system, clamping device, automatic feeding, material receiving rack, hydraulic system, electrical system, spray cooling system, automatic lubrication system, chain row conveyor It is composed of chipper, saw blade cleaning device and other parts.

Basic technical conditions of fully automatic high-speed metal circular saw machine

The fully automatic high-speed metal circular saw machine has reasonable design, advanced technology, and reliable safety protection, alarm, and insurance measures.

The parts of this equipment are made of high-quality materials, which are mature and reliable.

The measurement units of the equipment components, instruments and all drawings and documents all adopt the International Units (SI) standard.

This equipment can work normally and continuously under the conditions of ambient temperature -10~45℃ and relative humidity ≤95%.

The kinetic energy conditions of the installation environment of this equipment are:

1) Three-phase alternating current: 380V±10%, 50HZ±5%;

2) Compressed air: 0.4~0.6MPa;

3) Installation area area: 8.5m long x 2.90m wide x 2.30m high;

4) The hydraulic station is independently designed and placed inside the fuselage.

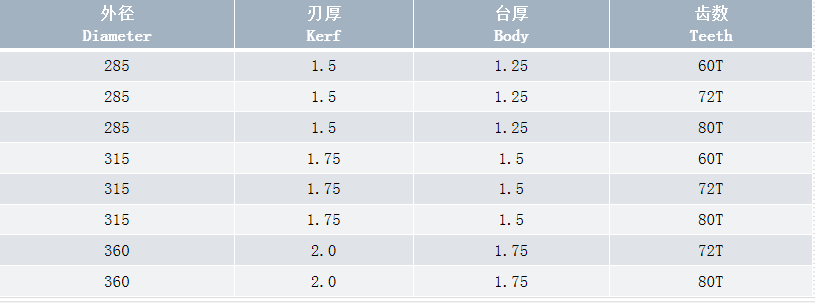

Stainless steel/metal cutting saw blade parameter requirements

Cold sawing, or metal cold sawing, is the abbreviation for the metal sawing process with a circular saw. During the metal sawing process, the heat generated when the saw blade cuts the workpiece is transferred to the sawdust through the saw teeth, and the sawed workpiece and saw blade remain cool, hence the name cold sawing.

Metal processing is a relatively difficult processing method in the field of sawing. The characteristics of the products being processed determine the high requirements and standards for the design, manufacturing and use of saw blades. As a result, there are more stringent standards for cold saw production and use equipment and operation details!

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com