Germany, Japan etc 80+ Countries.

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

Anyang Forging Press Since 1956

China National Forging Hammer Standard Drafter

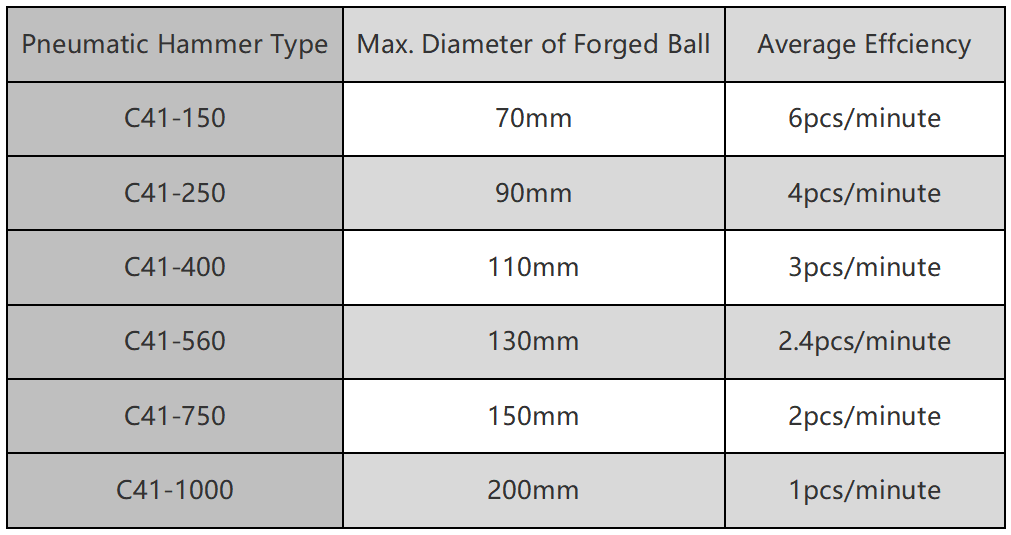

Pneumatic hammer forging steel ball less investment, fast running, can forge large range size steel balls. Steel ball impact resistance is good, strong toughness, good wear resistance, nonbreakable, and always round. The heating metal billet to be 1050 ℃ (error<= 50 ℃), pneumatic hammer forges the hot metal blank with a round die, the piece will become round. after forging can eliminate the metal casting defects, optimizing the microstructure, at the same time because of the intact metal flow, forging is generally better than the same material casting on the mechanical properties.

Forged steel balls are widely used in large mines, gold, copper, aluminum oxide, iron ore, aluminum, colorless non-ferrous metals, metal, non-metallic mineral rare metals precious metal, metallurgical mining, cement, building materials, thermal power, flue gas desulfurization, magnetic materials, chemical industry, coal water slurry, pellets, slag, ultrafine powder, fly ash, calcium carbonate, quartz sand and other industries of ball mill and rod mill equipment.

Forging steel balls diameter range is Φ20mm-Φ250mm.

High hardness. Surface hardness is 55-56HRC, volume hardness is 50-63HRC, the hardness graded distribution is average.

High impact toughness. Impact toughness over 12J/㎝2.

Low broken rate. Crush resistance is 10 times than the general casting balls, the actual breaking rate is less than 1% after more than 20000 balls impact testing.

No deformation. Forging steel ball will not out of round from big to small.

The quality difference between Forging balls and other making processes

If you want to learn more about forging machine, steel ball machine, briquette press or hydraulic riveter etc products, please send requirements to info@anyanghammer.com